New Delhi: Daikin Industries Limited, global leaders in HVAC systems, recently confirmed the success of their patented Streamer Discharge Technology to neutralize Coronavirus and Mouse Hepatitis Virus A59. The air conditioning giant confirms that the inactivation of SARS-CoV-2 exceeds 99.9% after it is exposed to Streamer Discharge Technology for 3 hours.

Dr. Satish Kumar, Executive Director of Alliance for an Energy Efficient Economy, in conversation with Mr. Kanwaljeet Jawa, CEO, and MD of Daikin India and President of Refrigeration and Air-Conditioner Manufacturers Association (RAMA), discuss the new Streamer Discharge Technology, its implications on India’s air conditioning market and policy issues governing the air-conditioning industry.

Dr. Satish Kumar – Daikin’s new Streamer Discharge Technology has been in the news lately and reports suggest that it could bring about positive change in tackling the spread of Covid-19. Could you please highlight Streamer Discharge Technology’s unique features and how people can understand it, especially in the context of the pandemic?

Mr. Kanwaljeet Jawa, CEO and MD, Daikin India

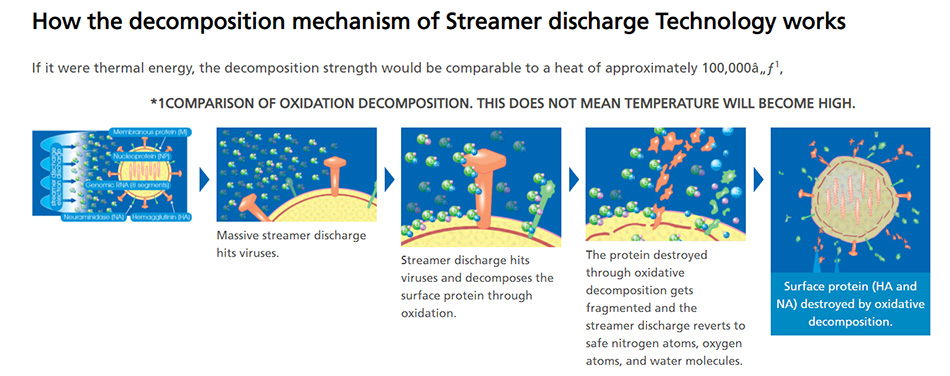

Kanwaljeet Jawa – Streamer discharge is a type of plasma discharge that generates high-speed electrons to perform oxidative decomposition of harmful substances. It has the proven ability to deactivate and eliminate viruses such as Influenza Type-A H5N1, MHV-A59, bacteria such as Tuberculosis, moulds as well as allergens and harmful chemical substances. Compared to the standard plasma discharge, which is a glow discharge, Daikin’s Streamer Discharge Technology’s discharge range is wider, making it easier for electrons to collide with oxygen and nitrogen particles present in the air.

In a nutshell, it enables the generation of high-speed electrons in three-dimensions, which speeds up oxidative decompositions by over 1000 times by consuming the same electrical power as standard plasma discharge.

SK – Many HVAC manufacturing companies and global leaders like Daikin, come up with technology to either dilute the contaminants or irradiate electrons like in this case, high plasma discharge, 1000 times more powerful. What are the energy implications of this technology?

KJ – There will be no energy implications as far as Streamer Discharge Technology is concerned, this technology consumes significantly low power consumption, which does not have any impact on overall energy consumption. Also, we keep energy efficiency at the core of our research and development of new technologies. Daikin Group has pledged to achieve net-zero CO2 emissions by 2050.

SK – Is this technology also available in Split air conditioners or is it only integrated in centralized HVAC systems?

KJ – We have some models of the Split air system which have this technology. Our flagship series uses Streamer Discharge Technology, which can be used for residential and light commercial applications.

SK – Daikin has invested $1.4 million and collaborated with Nature Architects, a start-up based in the University of Tokyo. The company is also participating in the Global Cooling Prize. There is a lot of buzz in terms of innovation, how the next generation of technologies are going to get developed, and whether they will be available for use in India. The concern in the Indian market is that most times, premium technologies are not readily available. What approach is Daikin taking to develop some of the next-generation technologies, and how are you ensuring that they benefit Indian customers?

KJ – India has been a very important market for Daikin Industries Limited. Our efforts are always directed towards delivering high-efficiency appliances at affordable prices. We spearheaded the use of eco-friendly refrigerant R-32, which has largely become the norm in the HVAC industry now. The size of appliances has become smaller, and their global warming potential (GWP) is much lower. After Japan, these innovations were introduced in India primarily because according to current statistics, 18% of HVAC industry’s potential customers are in India. The current penetration of air conditioners is about 7% in India, but the future looks bright. The Indian market, till last year, was importing almost 70 to 75%% of its components of air conditioners from these countries and some of the products were sub-standard, which means they were low on energy efficiency. The manufacturing units of many HVAC industries were shifted from China to Thailand and Vietnam to utilise the benefits of the Free Trade Agreement (FTA). The industry feels that local manufacturing will increase, and therefore, the latest technologies will definitely reach India.

In the last few years, we have witnessed revolutionary changes, and sizable investments are being made by multinational companies towards innovation, research, and development. The industries need to set up their plants in India at a rapid pace to utilize the opportunity that our country currently presents. Daikin plans to make India its manufacturing hub, which will render its appliances affordable as well as energy-efficient for the Indian customers. Daikin is also looking at this market as a major export hub. India’s population potential, combined with the Middle East and Africa, presents a total opportunity of approximately 35% in global sales of air conditioners in the future. Companies like Hitachi and Panasonic are investing here and trying to create and grow the Indian market together. Due to these measures, the market penetration of 7% is expected to double up to 15% fairly soon. The Indian market is going to gain further importance in the coming years. India’s market will undoubtedly have to be prioritised for new technologies that are developed. Daikin has already established its AI & IOT international centre in Hyderabad and plans to expand its mechanical R&D centre at Neemrana. Currently, we have 120 engineers in this facility. We are looking to support markets across the globe through these centres and continuously seek opportunities to collaborate with various start-ups and universities.

Our R&D Centre in Japan known as Technology & Innovation Centre (TIC) comprises the best engineers worldwide. They have worked on many innovations and have also successfully demonstrated the effectiveness of this unique Streamer Discharge Technology. We are focusing efforts on aligning with government bodies like the Bureau of Energy Efficiency, Ministry of Power, Bureau of Indian Standard, Department for Promotion of Industry and Internal Trade. We are also in discussions with the government to include other categories of air conditioners in star labelling.

SK – Being one of the leading HVAC companies, the company must be paying close attention and tracking the fast-evolving science behind some concerns that have been expressed about HVAC imposing a high risk of Covid-19. From R&D to marketing, what efforts Daikin is putting to create awareness about these deactivation technologies in the government arena and the public at large? How do you think that entities like AEEE, ISHRAE or other technical organizations can collaborate with companies like Daikin to spread the right information?

KJ – It is a challenge that we are well aware of. Some agencies have disseminated incorrect information due to a lack of knowledge about how HVAC technology works. It is quite upsetting because air conditioning actually helps patients in the healthcare facilities, and the false information that has been disseminated, points against it. This myth needs to be corrected at the earliest.

A few international associations have already prepared papers to address this misconception, and RAMA has also given clarifications in the public domain. It needs to be a combined and continuous effort. Daikin can show the path and work together with other manufacturers who are members of RAMA, The Indian Society of Heating, Refrigerating and Air Conditioning Engineers (ISHRAE), Consumer Electronics and Appliances Manufacturers Association (CEAMA), and civil society organizations like AEEE.

There are many NGOs that have taken the responsibility to spread this awareness. It is the need of the hour. We would like AEEE to support policy development for this on the forefront. The change in the mindset that has been created will be difficult to address otherwise.

SK – RAMA has recently selected you as the President. You have also alluded to the import ban imposed on refrigerant-based ACs, especially from China following border disputes in Ladakh. One concern that this ban has created is its effect on the price of the air conditioners for the consumers. How valid is this concern according to you?

KJ – To get the economy back on track, we need to look at it with a larger heart. While none of the Indians were responsible for the spread of Covid 19, it has definitely slowed down our economic growth. We have to start learning to compete with global manufacturers. An import ban has been imposed by the Government of India on import of Chinese goods and raw materials because of the tension created by the Chinese troops at the Indo-China border. The need of the hour is to manufacture locally, so that we can reduce imports. This has been emphasized by PM Modi in his Make in India initiative and pertinent steps have been taken. About $5-6 billion have been invested to boost local manufacturing of AC components, import duty has been hiked to discourage components being imported and the import duty fee with Thailand has been reworked. So, we as an industry, definitely appreciate these bold and proactive steps taken by our Government. This move will boost the Indian manufacturing capability, boost consumption and support the economy. Temporarily, the prices might go up but over a period of time, this will benefit the consumers. Confederation of Indian Industries (CII), The Federation of Indian Chambers of Commerce & Industry (FICCI), RAMA together with various ministries are proactively trying to address these concerns.

China is producing almost 110 million air conditioning units annually whereas in India sales were close to 7 million units in 2019 with 20 to 25% of which was importing from China/Thailand. There is a need for more and more global suppliers to enter the Indian market. Initially, it might be a challenge but we are trying to work with the right people at the right levels. When it comes to conductors being used in ACs, be it Aluminium or Copper, why should we source it from Malaysia or Thailand? We have the capability as well as the capacity in India. On one side we are increasing the capacity to create and grow the market, and on the other side we are also approaching the government. Ease of doing business has improved. Also, financial and fiscal support to the investors to attract investments and low interest loans for manufacturing investment, these measures will definitely support this move.

Prior to 2001, Room Air Conditioners (RAC) were drawing 2.8 kW or 14 amps. Today, there are air conditioners running at as low as 0.7 kW and 4 amps. So, we do have some challenges to face but we are definitely capable of addressing them. To sum up, we need to look at medium and long-term gains to boost domestic manufacturing, rather than short term pains in terms of price escalation. That is the only way India will get established as a global manufacturer.

Compiled by Shruti Saraf, with inputs from Dr. Satish Kumar, Nitin Kesar and Sandeep Kachhawa