The Hidden Costs of Rapid Construction: Environmental Challenges Posed by Aluminium Formwork Construction

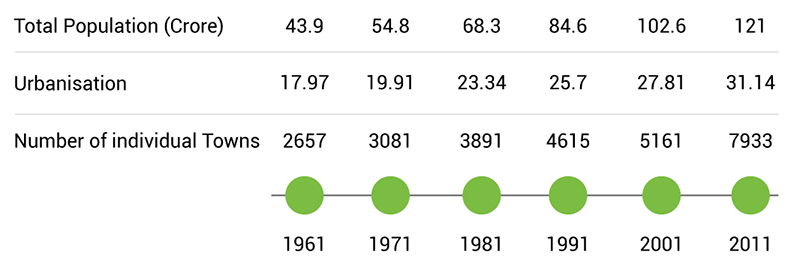

In a rapidly urbanising India, where the urban population has surged six-fold, rising from 62.4 million in 1951 to 377.1 million in 2011, the Government of India is promoting innovative and fast-paced construction technologies to address the growing housing demand in urban areas. This has become crucial considering the projection that by 2030, 590 million people will reside in Indian cities—an amount equivalent to twice the current population of the USA.

Figure 1. Decadal trend of demography, urbanisation and individual towns in India per Census 2011 data

Figure 1. Decadal trend of demography, urbanisation and individual towns in India per Census 2011 data

To support the Pradhan Mantri Awas Yojana (PMAY), the Centre launched Light House Projects (LHPs), promoting varied construction technologies for their affordability, cost-effectiveness, and timely delivery. Among these, aluminium formwork construction has gained popularity due to its efficiency and suitability for high-rise apartments. With the launch of PMAY-Urban 2.0, a significant portion of new construction is expected to utilise this technology due to its fast pace and consequent economic benefits.

Aluminium formwork construction, while efficient, introduces complexities in addressing the long-term environmental impact. Significant concerns exist around its impact on thermal comfort, operational energy demand, and associated emissions. These challenges necessitate a careful evaluation of the technology’s sustainability in the context of India’s growing urban landscape.

What is Aluminium Formwork Construction Technique?

In the aluminium formwork construction technology, aluminium forms are used to construct walls and slabs in one continuous concrete pour. In this system, traditional beams and column constructions are eliminated. Instead, walls and slabs are cast in one operation at the site using specially designed, easy-to-handle, lightweight, pre-engineered aluminium forms. This enables fast construction with minimum labour. It also facilitates savings in project costs due to the shortening of construction time.

Challenges Posed by Aluminium Formwork Construction

In aluminium formwork construction technology, external walls’ thickness typically varies from 100-150 mm with centrally positioned reinforcement. The thermal performance of these walls, which is measured using the metric thermal transmittance (U-value), remains poor. The U-value measures how much heat passes through a specific area of a building material over time, depending on the temperature difference between the inside and outside. A lower U-value means the material has better insulation properties, preventing heat from entering the building. In aluminium formwork construction technology, this leads to a U-value of approximately 3.7 W/m²K, compared to 2.3 W/m²K for brick, 2.2 W/m²K for fly ash and 0.77 W/m²K for autoclaved aerated concrete (AAC) block walling systems.

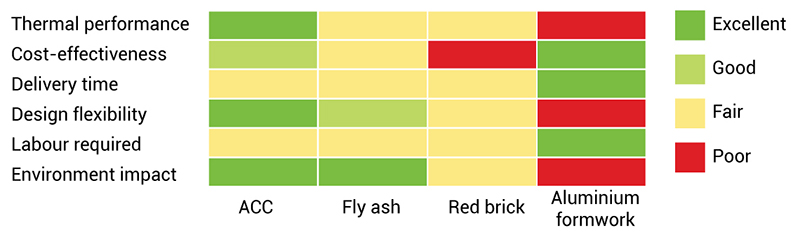

Due to the high thermal transmittance value, the building envelope constructed using aluminium formwork construction technology easily transfers heat from the outside to the indoor environment and creates thermal discomfort. Additionally, this type of construction contributes more significantly to environmental damage due to the use of emission-intensive materials like cement and steel. Embodied carbon, which measures emissions released during raw material extraction, transportation, and manufacturing, is notably higher for cement and steel— two and five times greater, respectively, than that of AAC blocks. The figure below maps the different walling materials from “Excellent” to “Poor” based on their thermal performance, cost-effectiveness, construction time, design flexibility, labour required and environmental impact.

Figure 2. Mapping of different types of walling materials with their thermal performance, cost-effectiveness and environmental impact

Figure 2. Mapping of different types of walling materials with their thermal performance, cost-effectiveness and environmental impact

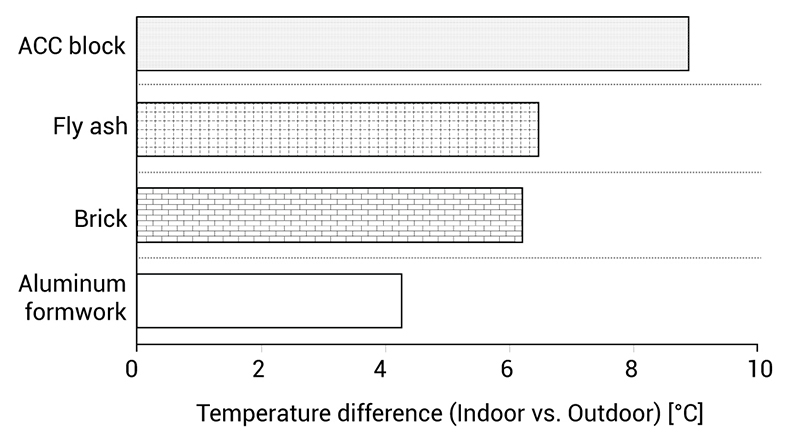

Last summer, we measured indoor and outdoor temperatures in around 20 residential houses across Delhi NCR, each built with different wall materials like Red Burnt Brick, AAC Block, Fly Ash Brick, and Reinforced Cast Concrete (RCC) using Aluminium Formwork. The results, shown in Figure 3, reveal that the temperature difference between indoors and outdoors varied from 4.2°C to 8.5°C during the peak summer hours, depending on the wall material. Buildings constructed with Aluminium Formwork had the smallest temperature difference, indicating less insulation.

Figure 3. Indoor vs. Outdoor temperature difference for various walling materials.

Figure 3. Indoor vs. Outdoor temperature difference for various walling materials.

The indoor environment of buildings constructed with Aluminium Formwork construction technology would be more thermally uncomfortable during heat waves, significantly increasing cooling demand. This surge in energy usage for cooling would not only put additional strain on the power grid but also raise concerns about grid resiliency, as the increased demand during peak periods would challenge the grid’s capacity to maintain a stable and reliable energy supply. Therefore, the widespread adoption of aluminium framework construction technology to meet growing housing demands, driven by its faster construction and reduced labour requirements, may prove to be a short-sighted solution—one that could ultimately create more problems in the future than it solves today.

The Way Forward

Aluminium formwork construction should be promoted with an appropriate insulation integration strategy to improve the thermal performance of the building envelope. While this approach may increase the initial construction costs, the higher upfront investment can be offset by the lower electricity bills due to improved energy efficiency and reduced cooling demand.

Further research and development in construction technologies and materials are necessary to ensure that rapid and affordable housing solutions do not compromise the thermal comfort and well-being of the residents. Policymakers should prioritise sustainable construction practices and incentivise the adoption of energy-efficient building materials and designs. By doing so, India can achieve Sustainable Development Goals (SDG) related to Sustainable Cities and Communities while also promoting environmental sustainability and enhancing the quality of life for its citizens.

Disclaimer: The opinions expressed in this article are those of the authors and do not purport to reflect the views of AEEE.

This blog is written by Dr Brijesh Pandey and Dr Rahul Ukey