Tackling embodied carbon from India’s building sector

The Paris Agreement calls for limiting the global temperature increase to “well below 2 degrees Celsius”, relative to pre-industrial levels. This makes it imperative to transition towards a net-zero economy, globally, at the earliest. For India, achieving the target of net-zero could appear to be challenging as it needs to fulfill development aspirations while trying to reduce greenhouse gas (GHG) emissions simultaneously.

The recent IPCC report highlights the urgent need to achieve radical emission reductions in the next decade in order to avoid catastrophic impacts of climate change. The scale of this task is considerable, and we are already at a critical point in time.

The buildings and construction sector plays a key role in accelerating the transition towards a low-carbon, resilient, and sustainable future in India. As one of the highly energy-intensive sectors in the country, it contributes greatly to overall GHG emissions as compared to other end-use sectors. According to Global Alliance for Building and Construction estimates, India’s total building floor area would be around 57.6 Billion m2 by 2050 from 15.8 Billion in 2015. This growth would also spur the demand for basic conventional construction materials like cement, steel, bricks, glass, etc. Studies suggest that demand for cement and steel (energy and emissions intensive building materials) in India would reach up to 1,360 MT and 755 MT by 2050, from 328 MT and 99 MT in 2019, respectively.

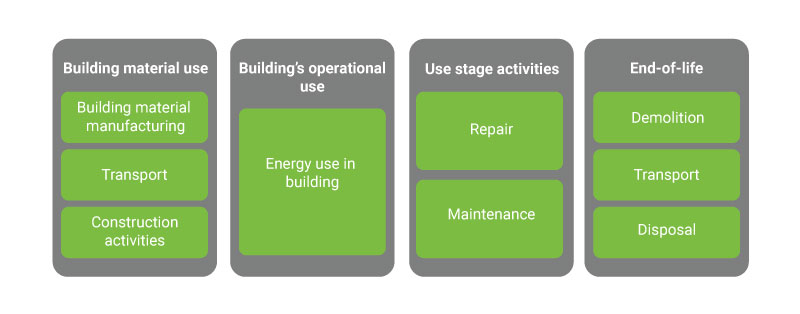

Energy consumption and carbon emissions in the built environment are largely born out of the use of electricity and building materials. The emissions associated to the energy use in a building are termed as operational emissions and the ones which are associated with building material production, construction of a building, renovation and repair and demolition at the end of life, are termed as embodied emissions. The different stages at which energy consumption and carbon emissions take place are depicted below in Figure1.

Figure 1: Stage of energy consumption and carbon emissions in buildings

Figure 1: Stage of energy consumption and carbon emissions in buildings

In the overall life span of a building, material use and building’s operational use account for majority of the carbon emissions. Whereas, the use stage activities like repair & maintenance and end-of-life stages has minimal contribution, as suggested in the research/pilot studies.

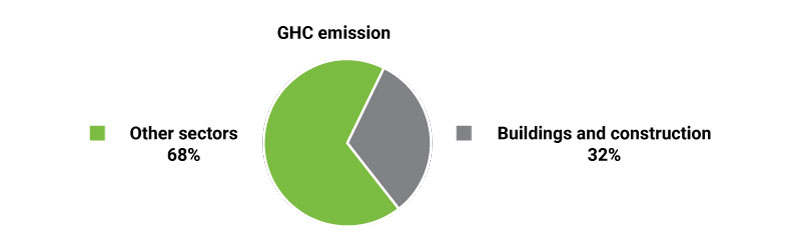

As per the data provided by India in the Third Biennial Update Report (BUR) (submitted on 20th Feb 2021) to UNFCCC, building and construction sector accounts for 32% of the total national GHG emissions inventory covering both operational and embodied emissions as depicted in Figure 2.

Figure 2: Share of building and construction sector in the overall national GHG emissions inventory

Figure 2: Share of building and construction sector in the overall national GHG emissions inventory

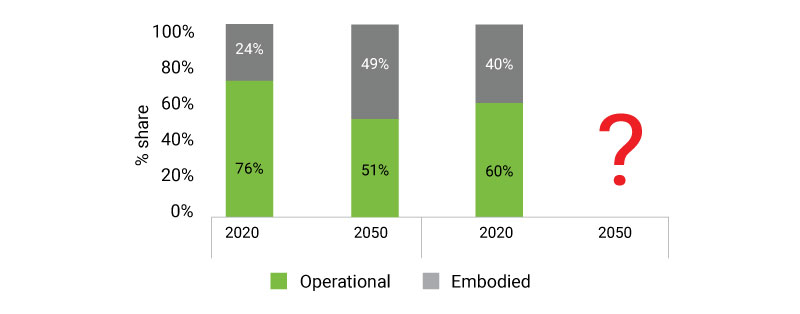

Within the building and construction sector, the split of embodied emissions and operational emissions is provided in Figure 3. It is evident that operational emissions, globally, are relatively higher, when compared to embodied emissions. But, according to estimated by “Architecture 2030” by 2050, accounting for all the building constructions happening between 2020 & 2050, the share of embodied emissions and operational emissions would become almost equal to each other. This is mainly due accelerated adoption of energy efficient technologies and renewable

Figure 3: % Share of embodied and operational emissions within the building and constructution sector

Figure 3: % Share of embodied and operational emissions within the building and constructution sector

On the other hand, for India, under the current scenario, embodied and operational emissions have a share of 40% and 60% respectively. This is primarily due to the lower level of appliance penetration in India and the prominent use of emissions-intensive building materials. There is need to conduct studies to estimate the scenario for India by 2050 to get a clear picture and take informed policy decisions.

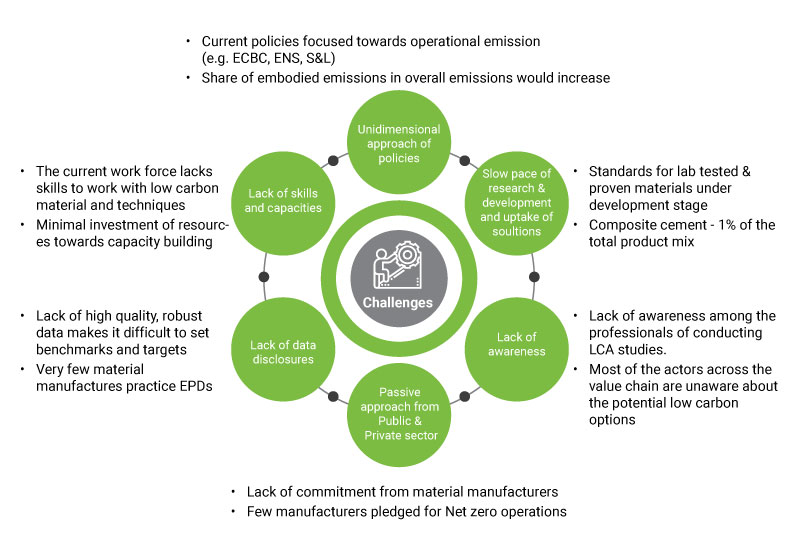

Currently, as part of the policy landscape of the building and construction sector in India, decarbonisation initiatives are mostly aligned towards addressing the operational carbon with very little focus on the life cycle approach covering embodied carbon. Building codes like Energy Conservation Building Code (ECBC) and Eco-Niwas Samhita (ENS) measure building performances based only on the operational use of the building and do not consider the embodied carbon aspect of the buildings.

Barriers to addressing embodied emissions

Abating embodied carbon from the building and construction sector may seem like a big challenge; understanding the barriers should be key to figuring out opportunities that would promote faster adoption of low-carbon interventions in the Indian building and construction sector. Below mentioned in Figure 4 are key challenges that that need to be addressed for decarbonization of this sector.

Global efforts (market and policy measures): Abating embodied emissions

Market leaders across the globally are working towards driving the efforts towards developing strategies for reducing the embodied carbon from the building and construction sector. These market leaders are increasing awareness of the associated challenges, identifying solutions such as carbon measurement tools, databases and benchmarks, and developing new business models that embrace lifecycle approaches and the circular economy. The table below summarizes major interventions taken in Europe and Australia towards addressing embodied carbon from the building and construction sector.

| Country | Major Interventions |

| Europe | Geopolymer Cement

Calcined clay cements

Low carbon steel making

Carbon Capture and storage

European green deal

Carbon border Tax

|

| Australia | Geopolymer cement

High blend cement

Mineral Carbonation

Minimizing use of cement

Carbon negative cements

Clean technology program

|

The buildings and construction sector is highly fragmented with different stages, processes and different stakeholders, and each stakeholder has an impact on the GHG emissions in the building life cycle. The complete decarbonisation of the building and construction sector is a daunting task and requires a clear and focused strategy with a holistic approach, covering all phases of building construction, from the extraction of building raw materials to the disposal and recycling of demolition waste.

In India, various actors across the value chain of the building and construction sector have started to realize the gravity of the situation and stared efforts towards addressing the embodied carbon. Some of the cement manufactures (Dalmia cement, Ultratech cement and others) and building developers (Lodha Developers, Mahindra Lifespaces Developers Limited and others) have demonstrated a positive intent by committing to carbon neutral targets by 2050 or earlier. But still there is a long way to go. Recently, AEEE partnered with World Resources Institute (WRI) to carve out an impactful pathway to decarbonise the sector across the value chain and developed the business charter on “Value-chain Approach to Decarbonise the Building and Construction Sector in India”. There is need to promote triple-sector collaborations where the government, industry, and the civil society come together and demonstrate leadership and brainstorm towards feasible solutions for the same in the short, and long term.

This blog is written by Shirish Bhardwaj (Research Associate, Industrial Energy Efficiency), with inputs from Deepak Tewari (Principal Research Associate, Industrial Energy Efficiency).